Vertical Elevator

Vertical Elevator by Golden Rolls

Absolutely essential and efficient components of any material handling system is the Bucket Elevator, which helps you raise materials up vertically.Every Golden Rolls Vertical Elevator is designed for handling bulk materials, and specialize in lifting large amounts of those materials vertically through the system. You will require our Bucket Elevator for lifting various quantities of iron ore, dry materials like sand, powder, flour, paddy, rice, lentils, various types of grains and seeds, nuts, coffee beans etc. There are many different types of materials that these elevators are capable of handling, across a wide variety of industries.

Golden Rolls

Bucket Elevator for Silos

Depending upon your Silo Tank capacity and input raw material, we design an integrated belt conveying system with Bucket elevator lifting and feeding the chain conveyor for filling up the silo tanks. We provide integrated Motorized or Pneumatic gates on chain conveyor as well as on silo discharge chutes with magnets for easy management of Silos and the production processes. Platforms are designed and built on Elevator for maintenance activity as per the drawings specifications.

Of course, there are also multiple different types of buckets from which you can choose depending upon the industry and material compliance like PVC, food grade poly buckets, MS, SS and GI. Your choice depends on exactly what you intend to lift, how much you want to lift and the kind of material processing system you have.

Bucket Elevator Capacity Indicator

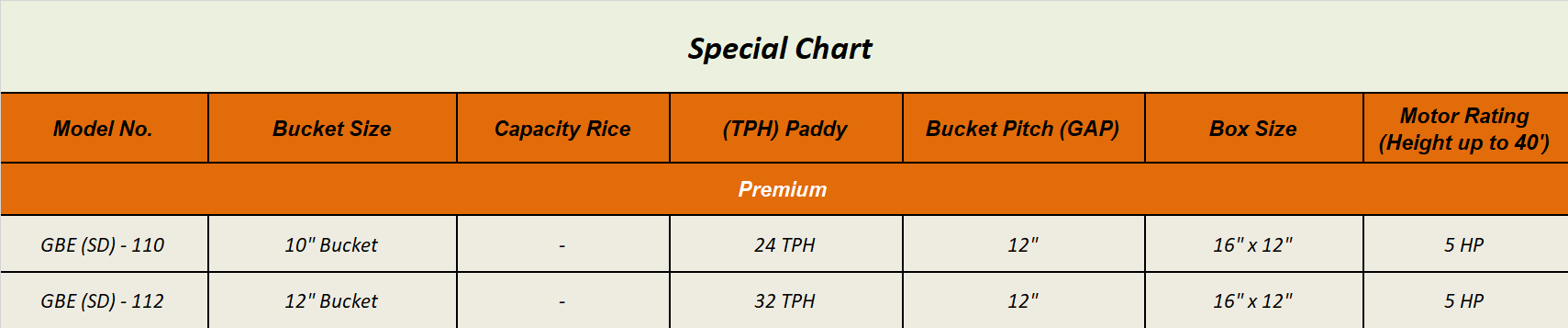

We fabricate Bucket Elevator of up to 20 inch bucket size in Carbon Steel, Stainless Steel and Galvanized Steel.

Raise your Materials – Elevate your Productivity.

- Tough and Heavy duty structures to last for decades

- No welding joints, completely bolt able structure for easy assembly

- No nut bolts inside the box for belt protection

- Heavy duty top and bottom pulleys

- Wide opening window for maintenance activity

- Back stopper arrangement to avoid material chocking

- UHD lining on discharge chute for prolonged life

- With or without maintenance platforms

- Only first grade branded components and material used

- Available from 3 meters to up to 30 meters height

- From 4 inch bucket size to 16 inch for various capacities

- Specialized slow speed elevator for specific applications

- Long lasting PU paint or Powder Coating finish

- Available in 110V / 220V single and 3 PH motors

Why buy from us:

- Designed for long rugged service life and gentle handling of the material

- Heavy duty pillow block head shaft bearing with end caps for dust protection

- HDPE Buckets / MS / SS and GI also available

- Easy clean boot, with a sliding tray at the bottom

- Inspection doors located on suitable height for bucket service

- Capacities calculated at water level cup for realistic capacities

- Split bonnet/ headcover for ease of maintenance of head section

- Strong multi-ply conveyor belt

Golden Rolls

Bucket Elevator for Grain Processing Units

Bucket Elevator feeds various processing machines like Pre Cleaners, De Stoners, Polishers, Hullers, Paddy separators, Fine Cleaners, Sortex, Size Graders etc. in all grain processing mills like Rice, Flour and various pulses.

All these elevators have various capacities and heights. We can design the entire system for you or fabricate as per your specifications. Whether its long haul mining industry or tiny processing units, we have integrated solutions for most of SMSE and MSME enterprises for bulk material handling requirements.

From raw material receiving point to final product packing line to loading bay, we are capable of providing complete solutions as per your specifications and needs.

Good Bucket Elevator Performance Starts Here.