Pre Cleaner by Golden Rolls

Cleaning has always been an integral part of grains, beans, pulses, nuts & seeds milling industry. It helps remove unwanted materials from the incoming raw material, such as husks, chaff, soil, and stones. Besides cleaning, it increases the overall quality of processed products and also prolongs the storability of material.

Golden Rolls designs and fabricates post harvest Pre Cleaner in various models from 2 TPH to 50 TPH capacity. These highly efficient machines are made to last for decades. The easy to maintain design makes cleaning and replacing the screens a time saving task and is ideally suited for the processing, handling & sorting of seeds, spices, grains, tea, coffee, pulses, all varieties of Rice & paddy.

Golden Rolls Post-Harvest cleaning Solutions are earmarked with characteristic efficiency, quality and reliability that are becoming favourites with business houses that we have served in India and Overseas markets. Our focus has always been to bring to our customers the best of the pre cleaning solutions with tested technologies and outputs.

Golden Rolls

Pre Cleaner

Large Capacity Pre Cleaner with Single & Double wooden decks are most suited in big size milling units requiring large capacity raw material cleaning. Golden Rolls wooden deck pre cleaner are designed to handle such large quantities of input raw material from 5 TPH to 45 TPH capacities.

When paddy comes into the mill from farmers, it contains lots of foreign materials, such as weed seeds, soil, stones, reel, rubbish, and other non-grain materials. Pre-cleaning helps remove these materials to improve the efficiency of huller and milling recovery. Non removal of this foreign material can result in damage to the supporting machinery and blocking the bin outlets which may create major shutdown and loss of resources.

While Pre Cleaning, the grains are passed via a sieve drum and are rotated in a sieve cylinder (Drum Sieve Optional). The brush attached in the sieve cylinder keeps cleaning it. The product flows over the magnet installed in it which functions as a speed breaker to remove dust and impurities. The grain is separated according to their sizes with the help of separators. The aspiration channel emits the soil with the help of the connection pipe. The pre-cleaner consists of circular, drum pre-cleaner and clobber.

- Above capacities are based on Paddy. May vary as per the actual product.

- High Grade GI sieves. SS sieves optional.

- High quality & durable water & termite resistant multi ply wood for decks.

- Cyclone and Airlock available in all models as Optional equipment.

- Customized sieves available as per specifications provided.

- Available in 110 V and 220 V / 3 Phase models.

- Most of the Pre cleaner are container friendly for exports.

- Long Lasting PU (polyurethane coating) finish in choice of colours.

- Highly efficient and durable machines in comparison to cost.

Golden Rolls

Specially designed PRE CLEANER

... for products requiring care while handling

Masters of Pre Cleaner Design & Engineering.

Golden Rolls builds only the well tried and tested Pre cleaner for the international market. We have machines with various sizes & capacities from 2 TPH to 50 TPH depending upon the product specifications. The Aspiration and Blowers are designed as per product and work efficiently for long periods with only the routine maintenance.

Our pre cleaner models come in Single and Double deck formation made with only the finest multi ply weather resistant wood with matching blowers, Cyclones and aspiration chamber. Our coated GI Sieves work tirelessly giving you trouble free service life and accessories and spares are available, if required.

Rest assured, once you order a GOLDEN ROLLS machine, you won’t look for any other brand elsewhere because after all our machines are “made Tough for the Rough”, not to mention the attractive price they come with.

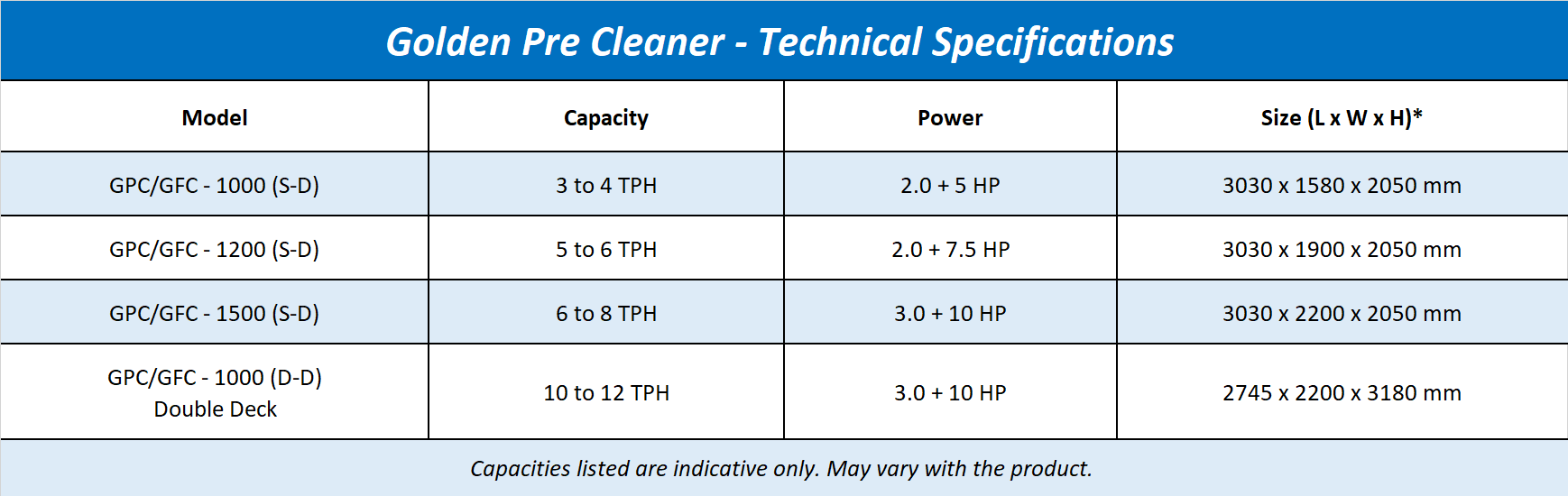

Please check below the specifications of our various models to cater to your needs. Since the chart is based on “Paddy”, please take the figures as indicative only. Please check with us for technical specifications of the product you want the pre cleaner for.

Why buy from us:

- Low energy consumption, high capacity and efficiency.

- Double sieve compartment box is fitted with 2 vibro balanced motors to remove big and small impurities.

- Removes small broken pieces as well as impurities.

- Available with cyclone, blower fan, air lock and geared motor (optional equipment).

- Independent aspiration chamber.

- Effective in all kinds of grains, pulses, seeds and beans.

- Two stage cleaning process.

- Can be used in grading of intermediary as well as final cleaning.

- Easy to clean and easy to maintain design.

- Capacities available from 1.5 TPH to 50 TPH depending upon the product.

VIBRO SEPARATOR (MTR)

About

It is a combined machine used to separate wheat grains from foreign rough materials using sieves based on size. Large grains are separated from small grains by sieve system.

WORK PRINCIPLE

It has a double-layered frame made of profile material and a sheet-metal sieve attached to it. The product entering the separator is sieved by the vibration of the vibro motors placed in the canter of gravity of the machine and spreading to the surface of the sieves. Garbage, straw, spike etc. foreign materials in the product are rejected through vibration out of the machine. The product is cleaned by separating the product from the broken vibrations. Sieve surfaces are continuously cleaned by plastic balls located inside the sieve. There are mica glass windows on the machine to watch the product. Since the vibro motors are mounted directly on the machine, no belts, pulleys, bearings and suspension rods are used. Sieve casings have easy disassembly feature.

FEATURES AND ADVANTAGES

- Low energy consumption, high capacity and efficiency.

- Double sieve compartment box is fitted with 2 vibro balanced motors to remove big and small impurities.

- Removes small broken pieces as well as impurities.

- Available with cyclone, blower fan, air lock and geared motor.

- Independent aspiration chamber.

- Effective for all kinds of grains.

- Two stage cleaning process.

- Can be used in grading of intermediary as well as final cleaning.

- Easy to clean and easy to maintain design.

Model GR MTR 1000

Capacity: 4–5 TPH Power: 1 HP + 1 HP GI Sieves 1700 x 1730 x 3022 mm

Model GR MTR 1200

Capacity: 5–7 TPH Power: 1 HP + 1 HP GI Sieves 1700 x 1930 x 3022 mm

Good Pre Cleaner Performance Starts Here.